AngleLock Technology Overview

Comprehensive introduction to AngleLock's revolutionary multi-plane mechanical locking system and how it outperforms traditional T-slot connections.

AngleLock Assembly Demonstration

Step-by-step demonstration of how AngleLock's patented fastening system creates superior connections that rival welded steel strength.

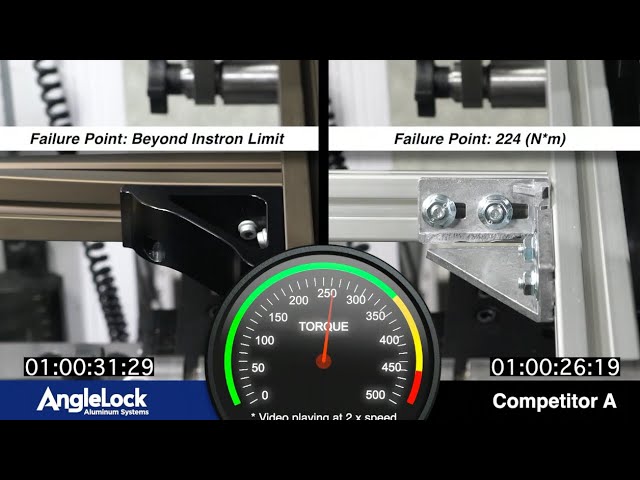

AngleLock vs T-Slot Comparison

Watch real-world testing demonstrating the superior strength, vibration resistance, and long-term reliability of AngleLock connections compared to traditional T-slot systems.

Five-Plane Locking Mechanism

Detailed technical walkthrough of the five-plane locking process that eliminates pivot points and creates mechanically bonded connections.

AngleLock Application Examples

See how AngleLock technology is used in demanding industrial applications including aerospace, robotics, semiconductor, and life sciences.

AngleLock Structural Testing

Watch load testing and vibration analysis demonstrating AngleLock's 10x strength advantage and zero-maintenance performance.

AngleLock Installation Guide

Learn how to assemble AngleLock structures 50% faster than traditional methods with our comprehensive installation guide.

AngleLock Product Features

Explore the key features and benefits of AngleLock aluminum framing systems for precision engineering applications.

Technical Analysis of Connection Technologies

AngleLock vs. Traditional T-Slot Systems

1.0 Introduction: The Critical Role of Connection Integrity

Modular aluminum framing systems are foundational components in a vast array of modern industrial settings, from automated manufacturing lines to aerospace assemblies. In these demanding environments, the strategic importance of structural integrity, precision, and long-term reliability cannot be overstated. The performance of a multi-million-dollar robotic cell or a critical work platform is ultimately dependent on the integrity of its smallest connections.

2.0 Traditional T-Slot Fastening System

The core mechanism of a T-slot system is fundamentally reliant on friction. It employs a high-torque, oversized fastener to generate a clamping force between components, creating frictional resistance to movement. This single-plane friction model creates "pivot points" between connected profiles—a central design flaw that compromises stability under non-static conditions.

Consequences of Pivot Points:

- •Movement and Slippage: Dynamic forces overcome static friction, causing component movement

- •Misalignment and Loosening: Microscopic movement causes fasteners to loosen over time

- •Profile Distortion: High torque measurably distorts profiles beyond extrusion tolerances

3.0 The AngleLock System: Multi-Plane Mechanical Locking

The AngleLock system was conceived as a direct engineering response to T-slot weaknesses. Instead of overwhelming dynamic forces with friction, it employs a patented mechanism that eliminates pivot points entirely through a sequential, multi-stage engagement across five distinct planes.

Five-Plane Locking Process:

- 1-2.Planes 1 & 2: Specialized nut anchors in V-shaped profile area, preventing rotation

- 3.Plane 3: Nut rotates up and locks into opposite profile side

- 4.Plane 4: Upper bracket slides into precision-aligned position with profile

- 5.Plane 5: Appropriately-sized bolt stretches, creating spring tension that completes the mechanical lock

4.0 Comparative Performance Analysis

| Performance Metric | Traditional T-Slot | AngleLock System |

|---|---|---|

| Core Connection Principle | Single-plane frictional force via high-torque, oversized fastener | Multi-plane mechanical lock creating bonded connection |

| Structural Feature | Creates pivot points between components | Eliminates all pivot points via multi-plane anchoring |

| Dynamic Load Performance | Prone to movement, slippage, misalignment, and loosening | Stretched bolt acts as spring to maintain alignment and resist separation |

| Long-Term Reliability | Susceptible to alignment loss over time, especially with vibration | Long-term predictability—assemblies don't loosen or misalign |

| Profile Distortion Risk | High torque measurably distorts profiles beyond tolerances | Appropriately-sized bolt mitigates distortion risk |

5.0 Empirical Evidence: Precision in Demanding Environments

Robotic Mounting

±5 microns

Repeatable positioning accuracy in robot mount applications

Docking Cart Accuracy

±0.003"

Repeatable accuracy with variance only from cart wheels, not locking mechanism

These precision levels are mission-critical in aerospace, automation, material handling, and custom applications. The system's vibration resistance makes it ideal for environments with constant vibration—such as industrial compressor mounting—where traditional friction-based fasteners inevitably fail.

6.0 Conclusion: Superior Structural Integrity

The T-slot system's reliance on single-plane friction introduces inherent, predictable failure modes under dynamic conditions. Pivot points guarantee susceptibility to slippage and loosening—an unacceptable risk in high-consequence applications where precision and structural integrity are paramount.

In stark contrast, the AngleLock system represents advanced engineering. Its multi-plane mechanical lock systematically eliminates pivot points by creating a "bonded connection" where tensioned bolts act as springs, actively maintaining alignment and resisting separation.

For demanding industrial applications where unwavering precision and absolute structural integrity are non-negotiable, AngleLock technology is not merely an alternative, but a fundamental upgrade—providing engineering certainty required to mitigate operational risk and guarantee long-term asset performance.